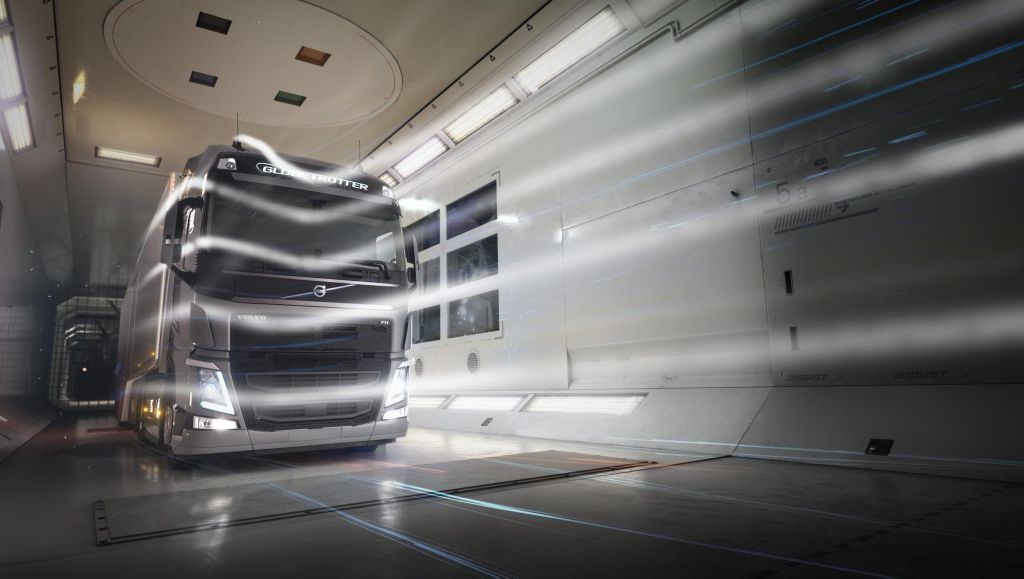

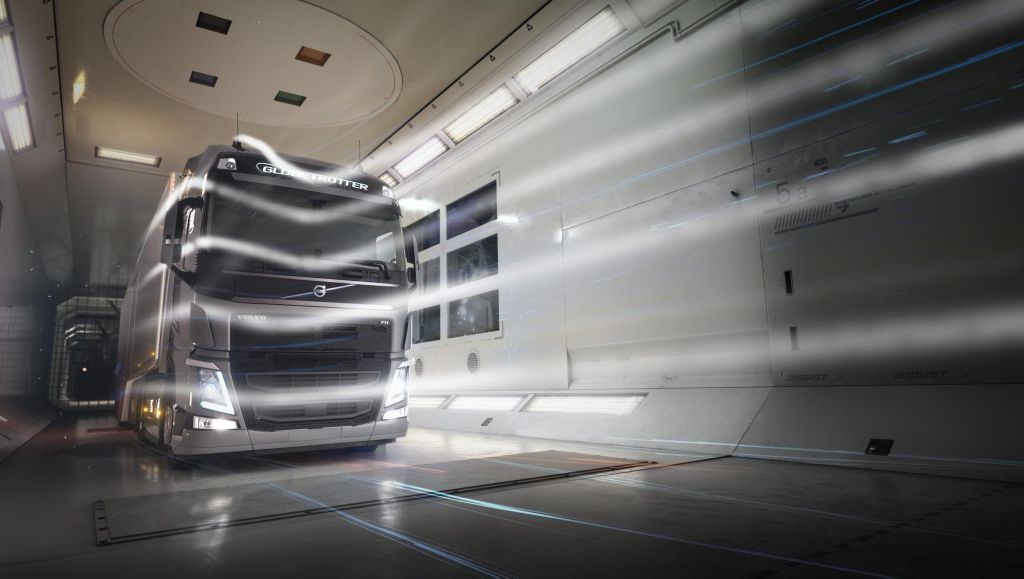

Ditching the drag with improved aerodynamics

When a truck is driven at constant speeds of 60-90 km/h, air resistance is one of the factors that has the greatest impact on fuel consumption. For many years, Volvo Trucks has therefore devoted considerable attention to the development of aerodynamics. There are a number of projects centred around applications that can significantly reduce air resistance. These will be introduced to the market stepwise in the years to come.

Part of the results of these efforts are the aerodynamic improvements that were launched in the spring of 2016, which include the optimisation of the Volvo FH bumper spoilers, air deflectors, wheel arch area and mudguards. Along with the new EURO 6 step C engine, these improvements will be introduced as standard in the newly produced Volvo FH model from June 2016.

“Even when the new Volvo FH was launched in 2012, major development work had been done to achieve as low air resistance as possible, given all the other requirements that our customers put on the truck. Since then, we twisted and turned every area of the truck, scanning it to see where an improvement would yield the greatest results for our customers,” says Anders Tenstam, Technology Specialist Aerodynamics.

A scan of the various loss areas and their improvement potential was carried out with the help of wind tunnel tests and computer simulations. Then it was all about making sure that the technology for the applications could be produced with the right quality and at a reasonable cost.

We twisted and turned every area of the truck, scanning it to see where an improvement would yield the greatest results for our customers.

“Working with advanced technology development is all about trying to anticipate the future needs of our customers and ensuring that the technology they want is available when regulations and cost levels allow for their introduction,” says Anders Tenstam.

In recent years, technological development has given Volvo Trucks new opportunities to improve the aerodynamic performance of its products. Rising fuel costs over the long term and growing awareness of climate issues are pushing customers to demand more fuel-efficient vehicles. This development towards higher fuel efficiency is in line with Volvo Trucks’ philosophy that every drop of fuel counts

The drive for fuel-efficiency is also affecting engine development: “We continuously strive to meet tighter regulatory requirements for cleaner engines without affecting driveability. Performance, productivity and driveability are extremely important for our customers and their drivers. We’ve always focused on responding to these requirements, but it must not be at the expense of fuel consumption. On the contrary,” says Mats Franzen, Product Manager for Volvo Trucks’ engines.

For Volvo Trucks, the advent of EURO 6 step C has resulted in a number of different optimisations for D11, D13 and D16 engines, such as pistons with less friction against the cylinder liner, a new and improved turbocharger and an optimised camshaft. Together with a number of improvements in the software, this enables lower fuel consumption without engine performance being affected.

It is a product that will provide significant customer benefits in terms of lower fuel costs and therefore higher profit margins, while maintaining performance.

“With our EURO 6 step C engine, we take another big step closer to the future of energy efficient transportation. It is a product that will provide significant customer benefits in terms of lower fuel costs resulting in higher profit margins, while maintaining performance,” says Mats Franzen.

For many trucking companies, fuel account for a third of their total costs. One haulage company that invests heavily in lowering its fuel consumption is Jastim, located in Warsaw, Poland. Jastim’s largest customers are Schenker, IKEA and DHL, three companies that attach great importance to environmental concerns and therefore put pressure on their suppliers to continuously reduce their fuel consumption.

Three years ago, before Jastim had bought any new Volvo FHs, the company’s average fuel consumption was between 31 and 32 litres per 100 km. Today, with the help of the Volvo FH trucks and additional Eco Driving programs, it is down to 26 litres. According to them, their best drivers are running at an average of 24 litres, and that, in favourable topographical and aerodynamic conditions, they achieve even lower consumption.

“What three or four years ago seemed impossible is now routine. It was extremely important for us to achieve such a large fuel reduction. In fact, we had no choice – our firm’s existence was dependent on this,” says Jastim’s owner Jacek Słowiński.

In order to remain competitive, his company regularly renews its fleet of vehicles, and the specifications for Volvo Trucks usually contain the latest applications for more fuel-efficient driving.

“We are interested in all new technological developments. Based on the amount of fuel we consume every month, an additional fuel saving of up to three per cent corresponds to thousands of litres for us,” says Jacek Słowiński.

Jastim is a long-haul Volvo Trucks customer with a strong focus on saving fuel. Volvo Trucks has therefore adopted the haulage firm’s specifications as the basis for the development of the new aerodynamic package. This is to create a tip alignment for customers driving at a relatively constant speed range of between 60-90 kilometres per hour and therefore benefit most from an aerodynamic improvement. Exactly how large a saving customers can achieve depends on their individual requirements and specifications, which in turn are controlled by the road conditions on the routes where their vehicles travel.

Based on the amount of fuel we consume every month, an additional fuel saving of up to three per cent corresponds to thousands of litres for us.

Anders Tenstam from Volvo Trucks is pleased that a new and flexible aerodynamic package for long-haul customers can now be introduced to the market. He sees great potential for further improvements, but acknowledges that technological maturity must be supported by new laws and regulations.

“Today, many countries’ regulations on vehicle length create a barrier to how much we can achieve in terms of aerodynamic performance. If tractor length was no longer included in the rig, for example, a more favourably shaped design could be introduced to the cabs. Today, the cab shape is the result of a delicate balance of features, both interior and exterior. A more aerodynamic cab would also then create more potential downstream on the vehicle, because of less pronounced large scale turbulence which steals energy in the front,” he says.

Anders Tenstam also emphasises that the trailers are an area of significant aerodynamic improvement. In future, this could result in an increasingly close customer collaboration on the design of sustainable transport solutions covering the whole vehicle and not just the truck itself. This in turn requires that practical solutions are developed, both on an engineering and a business level.

“Through our long-term focused development, we have seen that we should be able to come close to achieving the aerodynamic efficiency of passenger cars by addressing the strategic areas of the vehicle, cooperating on changes in applicable laws by applying a complete vehicle perspective. This could, in the not too distant future, mean slashing the air resistance to close to half compared with that of today’s trucks,” says Anders Tenstam.