What happens if an electric truck crashes into another truck? Or skids and rolls over at high speed? Anna Wrige Berling, Safety Director at Volvo Trucks, tells us how the company’s electric trucks are engineered to be crashworthy.

Battery electric trucks are becoming a more common sight on our roads. With safety at the core of Volvo Trucks, the company’s electric trucks are developed to be just as safe as all other trucks. One important safety aspect is crashworthiness, which is about developing vehicles that are resistant to the effects of a collision.

“Volvo’s electric trucks have the same cabs as our traditional diesel trucks, which have been thoroughly tested to ensure they are crashworthy. The electric trucks also have the same advanced safety features that are designed to prevent accidents from happening in the first place,” says Anna Wrige Berling, Safety Director at Volvo Trucks.

Virtual simulations and full-scale crash tests

Battery electric trucks have their own specific safety challenges, mainly concerning the electromobility system which includes a 600V battery. The risk of shortcuts and chemical leakage from the system needs to be minimized.

Volvo uses rigorous calculations, virtual simulations as well as full-scale crash tests to verify the safety of the electric trucks in the event of a crash.

“The calculations and virtual simulations are the foundation when we develop and verify a safe design for our electric trucks. In this way, we can test a variety of scenarios and parameters digitally. To verify the results from the simulations, we also conduct full-scale crash tests of the trucks,” says Anna Wrige

Crash tests that simulate real traffic situations

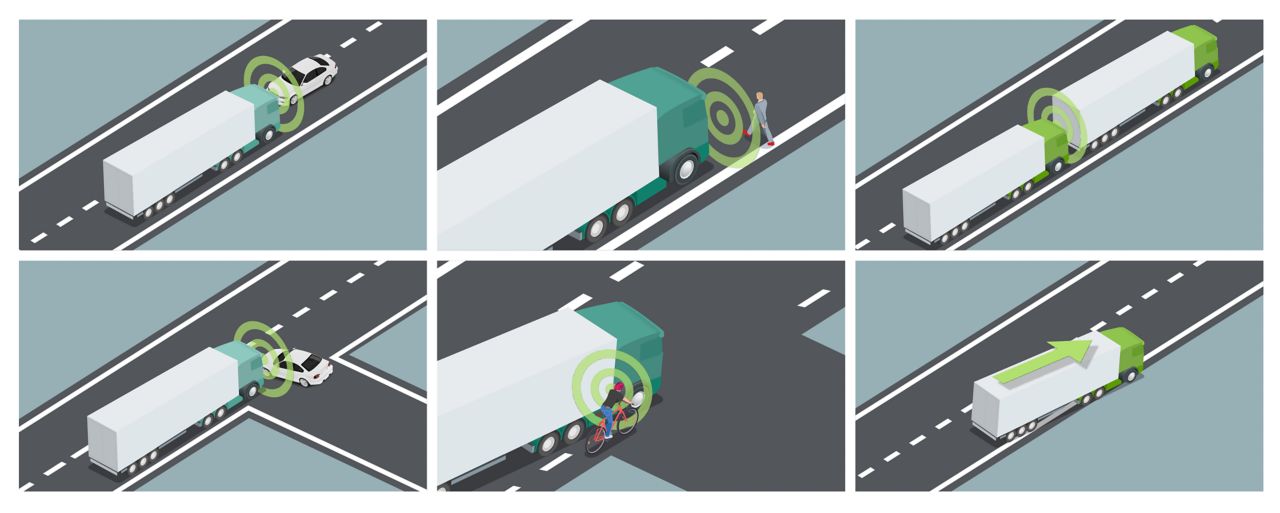

The crash tests simulate real traffic situations with the objective to verify requirements regarding electrical, chemical and fire safety.

“The purpose of the full-scale crash tests is to minimize the risk of fire and chemical leakage by verifying that the batteries and electric components stay in place in a crash, and that the high voltage system switches off,” she explains.

Three types of full-scale crash tests have been carried out on the Volvo FM Electric. The results of the tests confirm the positive results from the virtual simulations.

Volvo Trucks is the first global truck manufacturer to have a full range of electric trucks in series production.

“As forerunners, we have a great responsibility to ensure that the shift to fossil free, electric transport is done without compromising on safety – for drivers, rescue teams and for all other road users,” says Anna Wrige Berling, Safety Director at Volvo Trucks.