The Volvo FL Electric: How does it work?

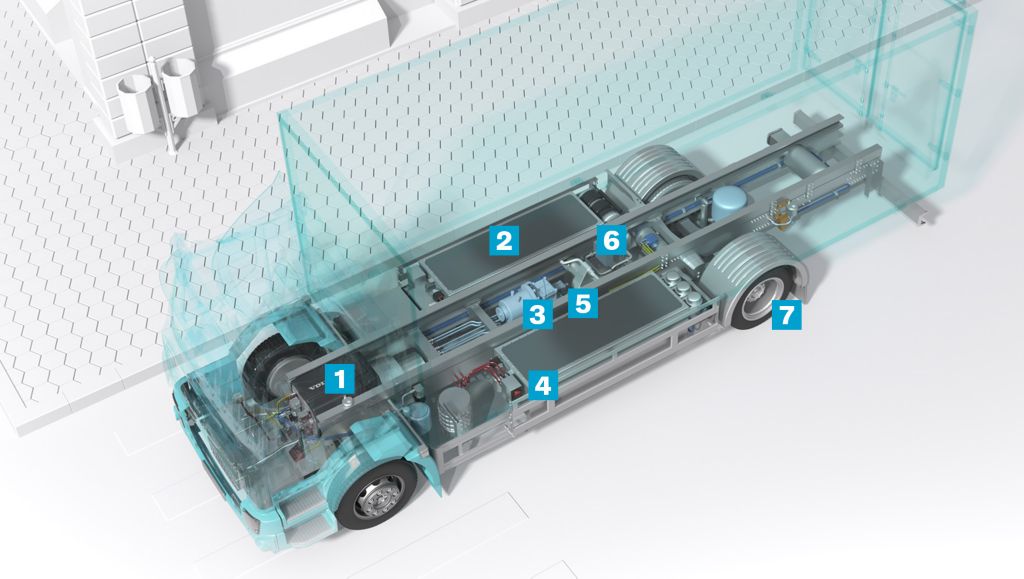

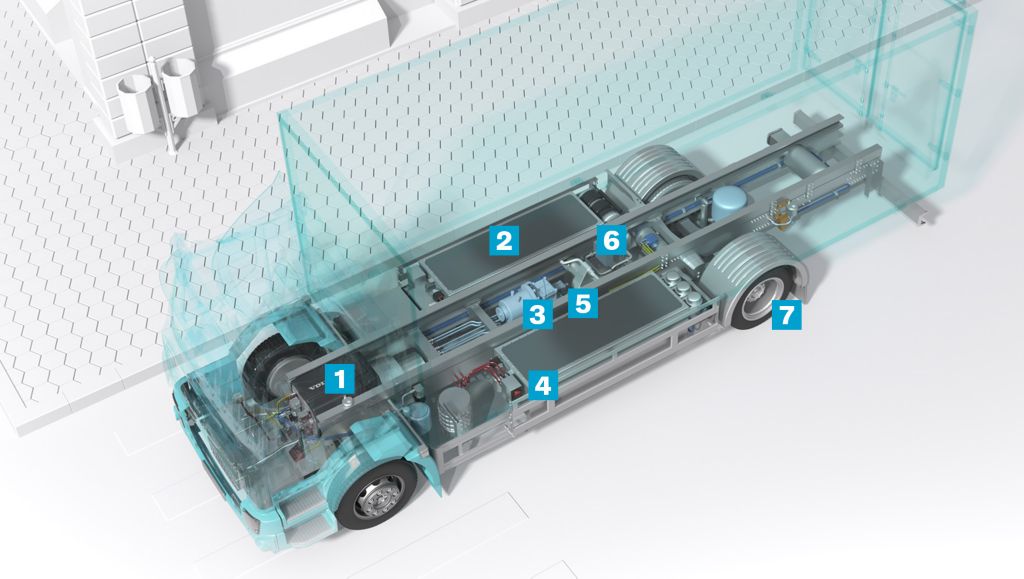

Performs a variety of functions including charging management and cooling management. It also includes 24V batteries, as well as 600V/24V conversion management mechanisms. Although the traction batteries run on 600V, 24V batteries are used to power electronics in the truck and in-cab facilities.

The Volvo FL Electric contains either four or six 600V batteries. Just like a regular battery, a truck battery produces electricity through a series of electrochemical reactions between the anode, cathode and electrolyte. In the Volvo FL the battery is made from low-weight Lithium Nickel Manganese Cobalt Oxide. Each traction battery pack has an energy capacity of 50 kWh and an estimated lifetime of 8-10 years.

As electric energy is supplied, it creates rotating magnetic fields, causing the rotor to spin. This provides the mechanical energy needed to turn the truck’s gears and wheels. The Volvo FL Electric’s permanent magnet motor has an output peak of 200 kW and 425 Nm of torque. The dimensions of the motor are carefully engineered to make it the smallest and lightest electric motor possible within the optimal range, both in terms of RPM and torque.

Both AC and DC charging of the truck is possible. This allows you to charge at industrial sites by using the onboard chargers. You can also charge at external DC stations for faster charging.

The 2-speed gearbox is designed and built by Volvo to be compact and light while making full use of the motor’s range. It enables seamless gear shifts and delivers maximum torque from start.

The air compressor supplies air to the air brakes. In the Volvo FL Electric the air brake uses Scroll technology to minimize noise levels, a special feature innovated for the medical industry that has been adapted to the trucks.

In electric trucks, regenerative braking uses the electric motor as a generator to convert much of the kinetic energy that is normally lost when braking. That energy goes back to the vehicle’s traction battery, where it is stored.

Long-life and high uptime

The owner benefits from high uptime, long component life and less frequent servicing. This is because electric motors are simpler, more compact and include fewer parts, compared to a conventional engine. And, since the truck runs on electricity, there are both fewer moving parts and fewer vibrations. The high uptime is also by design: in the Volvo FL Electric, for example, the ball bearings have been optimized for long life. The operating range of the truck is up to 260 km, depending on the number of traction batteries.

Volvo-designed gearbox

A major engineering solution that makes the Volvo Trucks’ FL Electric stand out is its unique Volvo-engineered and manufactured gearbox, which offers fully controlled and seamless power. This means drivers can start with maximum torque, even on steep hills. This, coupled with its light and compact motor, means the Volvo FL Electric driveline offers high performance. It can run on extremely low speeds of just a few kilometres per hour, making parking and manoeuvring in and out of tight spaces easy and smooth.

Reduced noise

A lot of thought and know-how has gone into achieving an almost silent and vibration-free truck. There is a 10 dB difference between the drive-by noise of a diesel Volvo FL and an electric version. That’s perceived as half as loud. While idling, there is almost a 40 dB difference! In fact, the noise emitted by a Volvo FL Electric during idling is lower than surrounding street noise. With a quieter truck, it’s easier to transport goods during off-peak hours – further adding to productivity.